Is Full-Grain Leather The Best Material For Durable And Natural Bags?

Worried about leather bags that crack and peel? This damages your brand's reputation and increases costs. Full-grain leather is the answer to building trust and lasting quality.

Yes, full-grain cowhide1 is the best choice for durable and natural bags. It uses the strongest part of the hide, retaining its natural grain and imperfections2. This results in a unique, long-lasting product that develops a beautiful patina3 over time, enhancing its value.

As a manufacturer with over 13 years of experience, I've handled every type of leather imaginable. I’ve seen brands struggle when they choose a material based on price alone, only to face a wave of warranty claims later. It’s a costly mistake. That’s why we always guide our partners, especially large-scale buyers whose brand reputation is on the line, to understand the materials deeply. Making the right choice from the start is not just about the product; it’s about protecting your brand and ensuring customer loyalty for years to come. We are here to explore why full-grain leather is almost always the right choice.

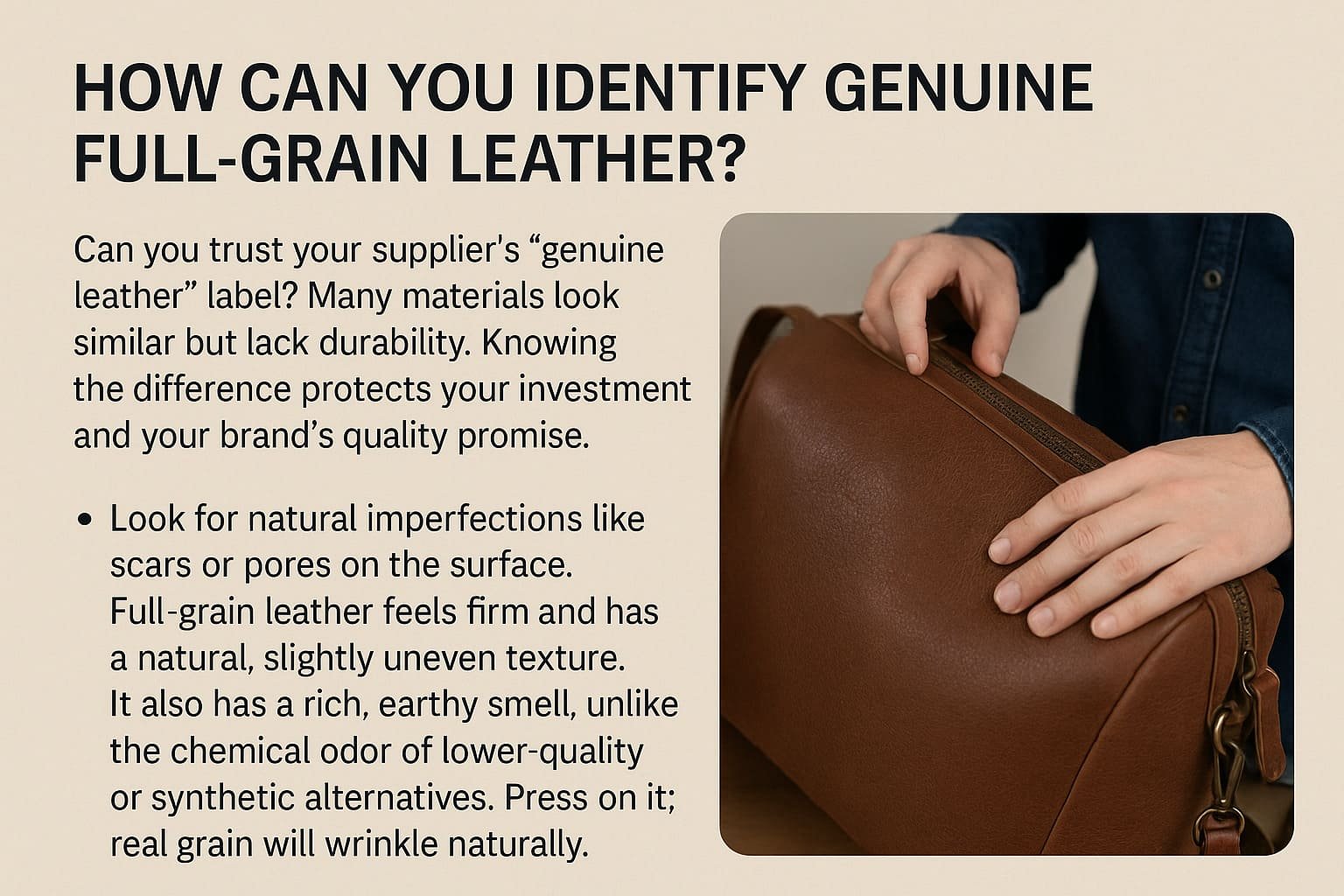

How can you identify genuine full-grain leather4?

Can you trust your supplier's "genuine leather" label? Many materials look similar but lack durability. Knowing the difference protects your investment and your brand's quality promise.

Look for natural imperfections like scars or pores5 on the surface. Full-grain leather feels firm and has a natural, slightly uneven texture. It also has a rich, earthy smell6, unlike the chemical odor of lower-quality or synthetic alternatives. Press on it; real grain will wrinkle naturally.

I remember a client, a procurement manager like Mr. Smith, who was about to sign a massive order with another supplier. He asked us for a second opinion. I took one look at the sample and knew something was off. The surface was too perfect, too uniform. I explained to him the simple tests we use. We look for the story that the hide tells. The small scars, insect bites, and wrinkles are not defects; they are proof of authenticity. They show the hide hasn't been sanded down or corrected. This is why we train our quality control teams to be experts in not just spotting flaws, but in recognizing authenticity. Here is a simple breakdown to help you distinguish between different leather grades.

Key Differences in Leather Grades7

| Feature | Full-Grain Leather | Top-Grain Leather | Corrected-Grain / Genuine Leather |

|---|---|---|---|

| Surface | Natural, with imperfections | Sanded and refinished | Heavily processed, artificial grain |

| Feel | Firm and durable | Softer, more pliable | Stiff or plastic-like |

| Durability | Highest, ages beautifully | Very durable, but less than full-grain | Lowest, prone to peeling/cracking |

| Breathability | Excellent | Good | Poor |

Understanding these differences is the first step to ensuring you are getting the quality your brand deserves.

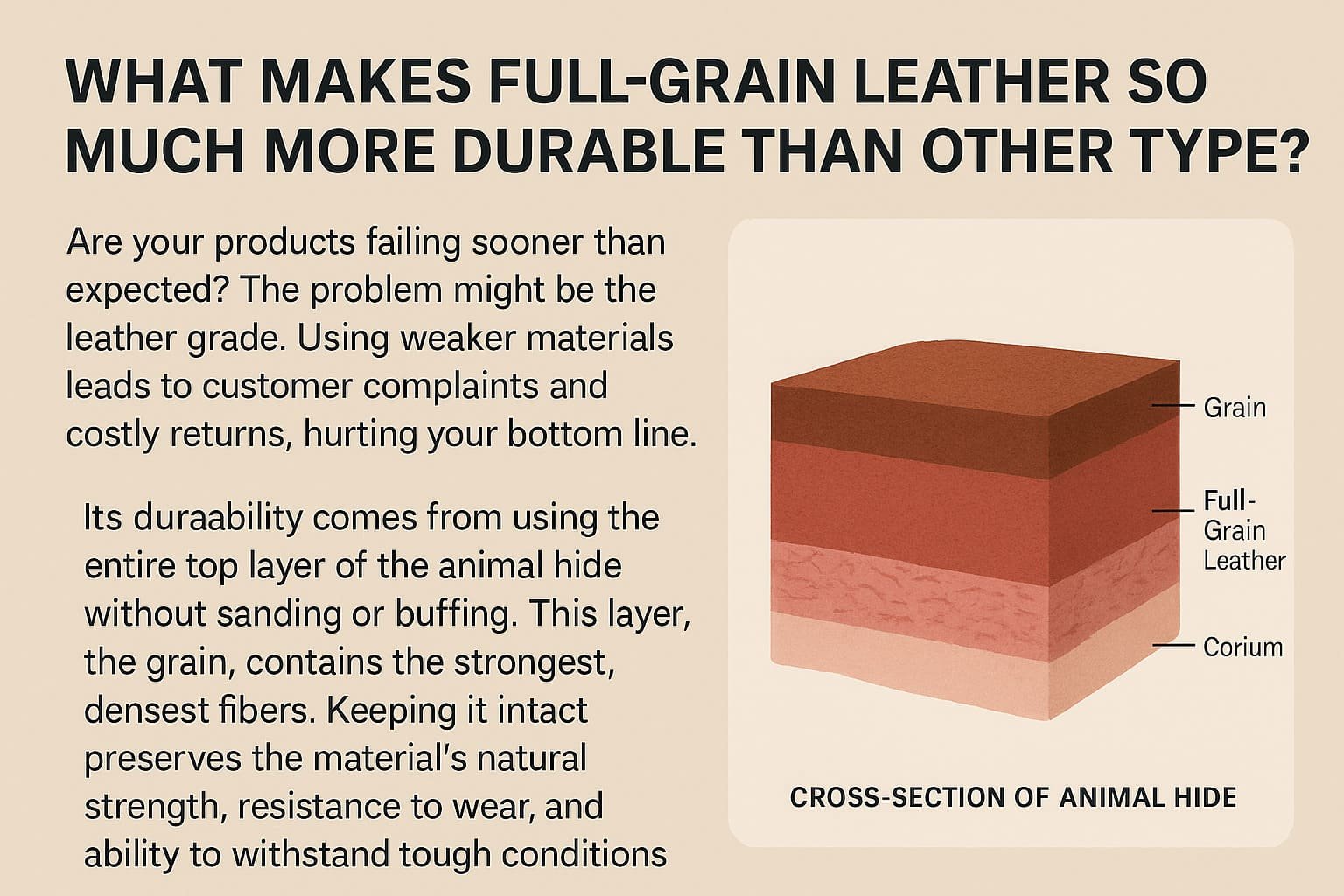

What makes full-grain leather so much more durable than other types?

Are your products failing sooner than expected? The problem might be the leather grade. Using weaker materials leads to customer complaints and costly returns, hurting your bottom line.

Its durability comes from using the entire top layer of the animal hide without sanding or buffing. This layer, the grain, contains the strongest, densest fibers. Keeping it intact preserves the material's natural strength, resistance to wear, and ability to withstand tough conditions over years.

The secret to full-grain leather's strength lies in its structure. An animal hide has several layers, but the outermost layer, right below the hair, is called the grain. This part is exposed to the elements throughout the animal's life, so its fibers are incredibly dense and tightly woven. When we create full-grain leather, we leave this layer completely untouched. We don't sand it, buff it, or correct it in any way. This preserves its natural structural integrity.

The Source of Strength

- Intact Fibers8: By not sanding the surface, we keep the strongest part of the hide. Other leathers, like top-grain, have this layer sanded off to remove imperfections, which weakens the material.

- Natural Oils9: The grain is also rich in natural oils, which help it resist moisture and stay flexible over time. This prevents it from drying out and cracking.

- Aging Process (Patina)10: Instead of wearing out, full-grain leather wears in. Over time, it absorbs oils from your hands and develops a rich, dark sheen called a patina. This process actually enhances its beauty and makes each piece unique, adding to its longevity and value.

For our clients with annual procurement over $5 million, this durability translates directly to a lower total cost of ownership. It means fewer returns, lower warranty costs, and a stronger brand reputation for quality.

Does your product line feel generic? Using uniform, corrected leather can make your bags look mass-produced. This lack of character fails to attract discerning customers looking for quality.

The natural texture tells a story of authenticity. Each mark and grain variation is unique, making every bag one-of-a-kind. This exclusivity elevates brand perception, justifies a higher price point, and connects with customers who value craftsmanship and true luxury over manufactured perfection.

In the luxury market, storytelling is everything. Customers aren't just buying a bag; they are buying a piece of art, a symbol of quality. The uniform, plastic-like finish of corrected-grain leather screams "mass production." Full-grain leather, on the other hand, whispers "craftsmanship." Each piece is different. A small scar might tell the story of a cow that brushed against a barbed-wire fence. The unique grain pattern is like a fingerprint—no two are exactly alike. This individuality is a powerful marketing tool. It allows you to sell not just a product, but an experience. It’s why we work so closely with brand managers on custom design solutions. We help them select hides that have the right character for their brand's story.

The Value of Authenticity

- Exclusivity12: When no two products are identical, you create a sense of rarity. This is a core principle of luxury branding.

- Emotional Connection13: The natural feel and look of the leather create a tactile and visual connection with the user. It feels real because it is.

- Perceived Value14: The visible quality and uniqueness justify a premium price. Customers understand they are paying for a superior, natural material that will last a lifetime.

A brand’s reputation is its most valuable asset. Using a material that reflects a commitment to authenticity and quality is a direct investment in that reputation.

How do we guarantee the quality of our full-grain leather?

Worried about inconsistent quality from batch to batch? Unreliable suppliers can cause production delays and damage your reputation. You need a partner who guarantees excellence every single time.

We implement a strict multi-stage quality control process15. We start by testing all raw materials to ensure they meet international standards like RoHS and REACH16. Our 8 production lines each have dedicated QC staff17 with over 5 years of experience, ensuring every piece meets our high standards.

For a purchasing manager at a large company, consistency is non-negotiable. A single bad batch can create a logistical nightmare. At classicalbriefcase, we built our entire manufacturing process around this principle. It is not enough to simply say we use full-grain leather; we have to prove its quality at every step. This commitment is why we are trusted by brands with massive purchasing volumes. Our process is transparent and rigorous.

Our Quality Assurance Protocol

- Step 1: Raw Material Vetting Before a hide even enters our facility, we test it. We ensure it meets strict international compliance standards like CE, RoHS, and REACH. This is crucial for our clients operating in global markets.

- Step 2: In-Process Inspection Each of our 8 production lines is staffed with its own dedicated Quality Control inspector. These are not junior employees; they are seasoned professionals with a minimum of five years of experience. They monitor every stage, from cutting to stitching.

- Step 3: Final Inspection18 Before any product is shipped, it undergoes a 100% factory inspection. We then perform a final random sampling check based on ISO 2859 standards19. This dual-check system ensures that the quality that leaves our factory is the quality you expect, every single time.

This disciplined approach removes the risks associated with sourcing. It provides the reliability and peace of mind needed to manage a high-volume supply chain effectively.

Conclusion

Choosing full-grain leather is an investment in durability, authenticity, and your brand's reputation. It ensures your products last, look better with age, and reflect a true commitment to quality.

Understanding full-grain cowhide helps you appreciate its durability and natural beauty, making it a top choice for quality bags. ↩

Exploring the significance of natural grain and imperfections reveals their role in enhancing the uniqueness and authenticity of leather products. ↩

Learning about the patina process shows how full-grain leather becomes more attractive and valuable with age. ↩

Identifying genuine full-grain leather ensures you invest in high-quality, durable products that stand the test of time. ↩

Understanding these imperfections helps you recognize authentic full-grain leather, adding to its character and value. ↩

A rich, earthy smell is a hallmark of quality leather, distinguishing it from synthetic alternatives. ↩

Knowing the differences in leather grades helps you make informed decisions about quality and durability. ↩

Intact fibers contribute to the strength and durability of full-grain leather, making it a superior choice. ↩

Natural oils in full-grain leather enhance its moisture resistance and flexibility, preventing cracking. ↩

The aging process, or patina, adds to the beauty and uniqueness of full-grain leather over time. ↩

The natural texture adds exclusivity and authenticity, elevating brand perception and justifying higher prices. ↩

Exclusivity in full-grain leather products creates a sense of rarity, enhancing their appeal and value. ↩

The tactile and visual appeal of full-grain leather fosters a strong emotional connection with users. ↩

Full-grain leather's quality and uniqueness justify a premium price, enhancing perceived value. ↩

A multi-stage quality control process ensures consistent quality, crucial for maintaining brand reputation. ↩

Compliance with international standards ensures safety and quality, essential for global market operations. ↩

Dedicated QC staff ensure each product meets high standards, maintaining consistency and quality. ↩

A final inspection guarantees that only top-quality products reach customers, safeguarding brand reputation. ↩

ISO 2859 standards ensure rigorous quality checks, vital for delivering reliable and high-quality leather products. ↩